The Storage System on the Home Version

I probably should have posted this article earlier. On

my former layout at the previous home, I built a storage traverser. It was, and

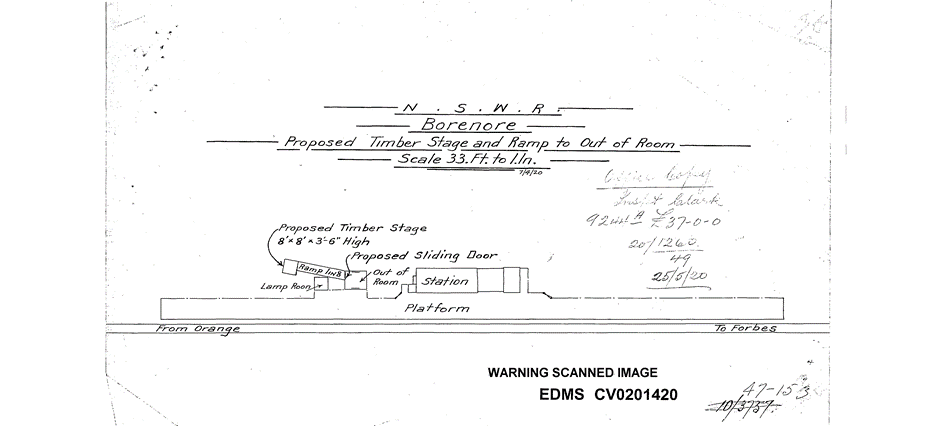

still is 2.68 M long. It has now been re-engineered for use with Borenore and

my branch line terminus called Balowra, a kind of mirror image of Eugowra that

is now being enhanced a little. Balowra also survived the move.

The re-engineering comprised of ditching the old L-Girder benchwork and risers

for direct mounting on two1.5 metre steel sliding door cabinets, which can also

store train storage boxes into the future. The new arrangement gives an

infinitely more stable base and better functioning traverser. I can now move

the traverser in and out by one hand without any binding. The sliders are now

mounted flat instead of vertically. I am still to build the connection to the remainder

of the railway but that will come as Borenore gains momentum.

The original traverser was the subject of a presentation at Modelling the

Railways of NSW, a joint presentation with my friend and colleague, Allan

Garbutt. It was re presenter at an NMRA Convention in Canberra. With Allan’s

permission I am posting the presentation here.

The new version is shown in the photos below.

The new deck fitted to the storage cabinets, the branch line models can be seen on their side in the background.

The new deck canter leavers over the cabinets

Traverser table refitted

Dust covers fitted, a must have.

The original MRofNSW Article reproduced.

Storage Yards

Building a better mousetrap

Presenters:

Phil Collins and Allan Garbutt

Introduction

Operational Storage has traditionally been represented by a

series of loops or single-ended sidings to store trains off-stage. The purpose of operational storage is to hold

as many full-length trains as possible and to provide “the other end” of the line. Unfortunately, traditional yard loops can be

expensive and reduce the amount of available storage space by up to 60%.

Traversers were used on the prototype to move a carriage or

locomotive from one track to an adjacent track in a confined location. An example of a prototype traverser can be

found at the Sydney Tramway Museum, Loftus.

This traverser originally came from the Clyde Engineering workshops

at Granville.

Within our model railway we can use the principle of a

traverser to great advantage to maximise operational storage within our staging

yards.

In model storage terms a traverser is much more like a well

built draw - and not limited to moving a single car at a time!

Traversers within model railways are not a new idea. There have been several articles within Model

Railroader and other model railway publications that describe various methods

of making a traverser. Commercial manufacturers

What we will be describing are the advantages and the tips

and tricks in creating a manually operated horizontal or vertical traverser.

The Horizontal Traverser Storage System

by Phil Collins

I first decided to use a traverser type storage system on my

second railway at my current home as the simple ladder yard system would give

me only about 40% of the storage capacity that a traverser would give me. I was

inspired by an article in December 2000 Model Railroader by John R. Signor.

However at the time I could not find suitable drawer slides so I settled for a

cassette system, albeit unwieldy. Sometime later a friend came over for morning

tea as part of his recovery from an operation and we got talking and within

minutes we were on the internet and found the drawer slides I needed. It is

good to have a mate who is a builder. A

quick trip to Wetherill Park the following week and I had two pairs of Hafele

Part No 422.83.345 drawer slides and the rebuild was underway.

These drawer slides had a load rating of 45 kg per pair and

were the fully extendable type. I calculated that a fully loaded traverser

would weigh approx. 39 kg, however I decided to use two pairs of slides (total

capacity of 90 Kg) to ensure stability over the 2.68 metre length and 0.45

metre width of the traverser.

The sums in favour of a traverser are indisputable. The cost

of two pairs of slides was $37.37, only slightly more today, verses

approx. $300 for the point work for a

ladder yard and the bonus is 2.5 times the storage capacity. You can see how

this factor of 2.5 is arrived at by comparing the two photos of my traverser

and a ladder yard overlayed on the deck. In the 0.45 metre width I was able to

lay 8 roads at 50 mm spacing, the remainder of the width being taken up by the

aluminium angle bracing used to stiffen the deck over its length.

1

Horizontal traverser in use

2

Example yard ladder in the same space

After some research I decided to use Trackrite urethane

track underlay on the deck. This had two benefits. Firstly it greatly reduced

noise, compared with say cork, and secondly its accurate 50 mm width made it

easy to locate the track. The Trackrite simply lays on the deck between the

aluminium edging, it is not glued down. The track sits in place and is held

there by one set of dropper wires and printed circuit board sleepers at the

ends.

The most difficult task in the building process was to

develop an indexing system to align each road with the on/off roads at either

end of the traverser. I finally settled on patio bolts aligning with holes in

more aluminium angle. Once each position was indexed the track was soldered to

the printed circuit board sleepers using a track alignment jig. The final task

was to install some form of isolating system for each road. When say road 6 is

aligned, roads 1,2,3,4 and part of 5 are sitting out over a 1 metre drop so

power to roads sitting out over the “drop” as it were needs to be cut off. I

achieved this by a series of micro switches under the deck working against an

aluminium angle fixed to the structure below the deck. The formula here was

simple. The micro switch cuts out power

to the track as each road moves out of alignment over the drop by half a track

width. This is very important as the layout is a DCC controlled railway with no

normal blocks, only the eight created by the isolating micro switches.

I guess the key to any engineering design is whether it

works. Well in this case it works extremely well. The only issues so far are

those associated with retro fitting it into an existing structure and ensuring

vertical alignment of the tracks. This problem is amplified in my case by the

structure sitting on a carpeted floor. Fortunately I have lots of 0.005 inch

styrene spacers at the ready! It is regularly abused by the members of the

NSWDCC Group and did not miss a beat during a visit by 70 members of the NMRA.

I might add that I used code 100 rail on the traverser and on/off tracks

transitioning to code 70 on the main layout section. This was largely due to

having the code 100 left over from a previous project but if I were building

one today from scratch I would not hesitate to use code 70.

The Vertical Traverser

By Allan Garbutt

The vertical traverser has some advantages including not

intruding into the horizontal aisle space, provides dust-free storage and

doubles as a display case.

The items to consider when designing a vertical storage and

display traverser are:

• Depth

required is a mere 130mm (5”)

• Wall Space

Allowance (Height);

The height above and below the approach track needs to be no

more than the total height of the traverser.

The length of the traverser needs to be balanced against the

total weight of the materials used and the number of tracks that it will

consist of. This particular vertical

traverser fits behind a door and uses 1200mm (4’) of wall space in the corner

of the room.

A pulley guide rope and counter weight was used to readily

shift the traverser through its range of movement. Movement is done by simply pushing the box up

or down and allows it to quickly move between any track in the display unit

(Random Access Storage).

The pulleys hold the weight of the traverser and the counter

weight. The entire traverser, including

trains can weigh in around the 25kg mark.

Make sure to check the load rating of the pulleys that you select. Exceeding the load rating could be dangerous

to the health of your trains. The

pulleys selected are made by Cowdry and support 30kg’s each.

The counter weight needs to balance the weight of the

storage unit including trains whilst remaining relatively thin. The material used is a cast iron BBQ hot

plate with some extra weight as required.

The weight required varies depending on the size of the display unit and

will need to hold the full weight of the display unit and an average load of

trains. The example traverser needed up

to 20kg+ once it is filled with trains.

Tracks must align within a fraction of a millimeter both vertically

and horizontally to ensure reliable operation of trains when entering and

leaving the display unit.

Cowdroy TRIUMPH Sliding Door Track System was used as a pair

of vertical guides. These ensure that the traverser moves smoothly and evenly and

stops unwanted horizontal and diagonal movement. The slides act as guides only and do not

carry any weight. The vertical slides

need to have a minimum tolerance to ensure correct track alignment.

The unit is locked in place by a patio security bolt. This security bolt has minimal manufacturing

tolerances and a built-in centre punch marking spike. This ensures accurate marking for drilling

holes to align the traverser and the approach track correctly.

Using these components will avoid damaging the approach and

storage tracks.

The traverser is used with both DCC and DC. A plug-in jumper cable is used to link to the

main layout bus. This pair is connected

to each track via a SPST isolation switch.

The SPST switch isolates one rail.

The traverser is operated by hand and the use of a SPST switch kept the

complexity to a minimum.

I used a quality piece of 9mm 3ply plywood for a flat back

panel. My main criterion was that the

back should be thick enough to take screws.

The shelves need to be cut square and straight to ensure

that they join at a 90 degree angle with the back panel. I recommend using a table saw or getting them

professionally cut. Normally your

supplier can do this for a small fee per cut.

Use a spacing jig to help ensure each shelf is correctly

spaced at approximately 4”.

3mm Perspex is used on the front because it is relatively

self-supporting and minimizes sag. Plastic

channel surround is attached to the top and bottom of the front to allow the

perspex to easily slide on or off. Some

C and H mouldings from Australian Plastic profiles, available from Mitre 10, were

used to manufacture a frame to hold the perspex. The parts used were 10mm x 2.4m Cap moulding

@ $5.50 for 9mm shelves and frame and 4.5mm x 2.4m “H” moulding @ $2.50 which was

cut to a “C” shape.

Atlas Code 100 rerailers (part # 150-844) are used at each

end of the traverser to make sure that each car is on the track as it enters and

leaves the traverser. An adjustment

screw and washer hold down the Atlas rerailer.

This screw and washer allows for a fine adjustment of the vertical

alignment of the track.

Code 100 track was used for the storage tracks. Trackrite urethane track underlay was used to

maintain correct track location on each shelf.

All track is laid loose on the underlay and does not need to be glued

down to the shelves.

3 The Vertical Traverser

Materials Listing

|

Part No |

Description |

Supplier |

|

150-844 |

Atlas Code 100 rerailers |

Any good hobby shop |

|

|

Code 100 Flex track |

Any good hobby shop |

|

H505A, H505B or H505C |

Trackrite underlay, any of the track

recess types |

|

|

S926 |

Pulley, Max 30Kg ea (sold in pack of 2) |

Any good hardware shop |

|

TT320 |

Top Mount Track – 2000mm |

|

|

S331 |

Pack of 2 TT331 Wheel Assemblies |

|

|

|

Cap mould 10mmx2.4m |

Any good hardware shop |

|

|

H mould 4.5mmx2.4m |

|

|

|

3mm Perspex |

|

|

|

Patio Bolt |

Any good hardware shop or locksmith |

|

SPDT Toggle switch |

Interesting Internet Links:

http://www.youtube.com/watch?v=dxRJ9rdyX4c

I would be happy to upload the Poerpoint Presentation as well but as a novice I do not have any idea how to do that. If you know how let me know.

Thanks for viewing.

.jpg)

.jpg)